MagPlate 24

- 24-Well Magnet Plate

- SKU: A000270

$880.00

Starting from 3 items: 5% off

Starting from 10 items: 10% off

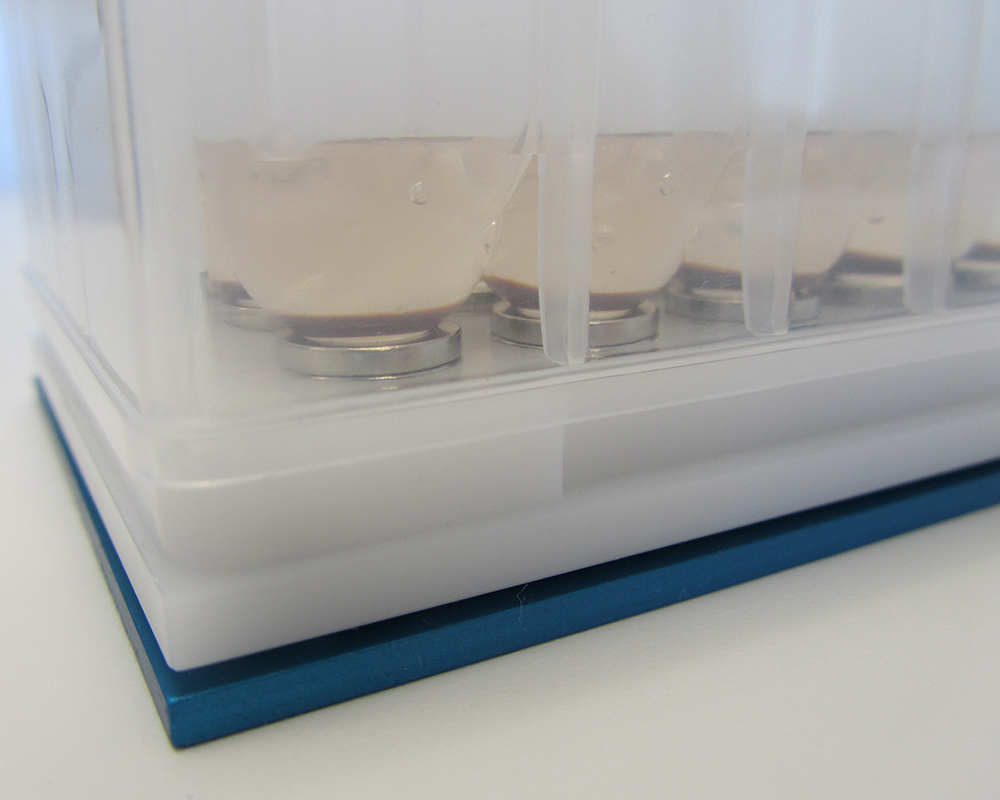

24-well magnet plate with concentric NdFeB ring-based magnets and integrated Spring Cushion Technology for rapid bead separation in large volume samples.

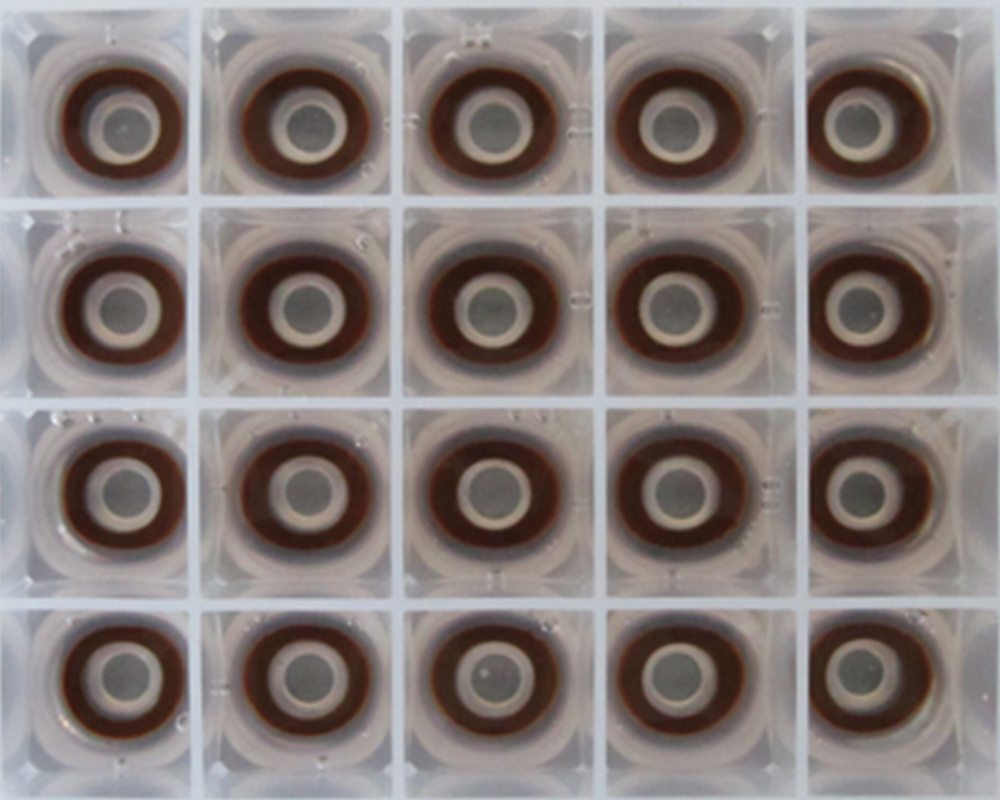

The concentric NdFeB ring magnet design of the MagPlate 24 provides for rapid and efficient bead separation from larger sample volumes.

Unique ring magnet architecture enables rapid and efficient bead separation in sample volumes as large as 10 mL.

Magnetic beads are sequestered at the outer edges of each well providing for simplified removal of supernatants using automated platforms. Designed for use with GE Whatman Uniplate 7701-5102.

Features of the MagPlate 24

- SBS-compliant footprint and optimized for use on robotic platforms

- Double ring magnet structure provides for rapid bead capture from viscous solutions or large volumes

- Strong NdFeB magnets for efficient bead capture

- Integrated Spring Cushion technology

- Compatible with common magnetic bead chemistries and protocols for product and application flexibility

- Designed for use with Whatman™ 10 mL UniPlates™

Why do I need Spring Cushion Technology?

Alpaqua microplates with integrated Spring Cushion Technology give way when tips come in contact with a well bottom, thus compensating for physical tolerances between labware and pipettors that can compromise precision aspiration. Alpaqua’s proprietary technology protects from tip vacuums, head contamination, and costly instrument repairs, while providing for maximum sample recovery and minimum dead volumes.

MagPlate 24 Resources

MagPlate 24 Brochure

A000270

MagPlate 24 Specifications

A000270

Product Passport – MagPlate 24

A000270MagPlate 24 FAQs

Is the MagPlate 24 compatible with the 16 mm tube rack (A000260)?

It is not. The center-to-center distance of the magnet plate is 18 mm (standard for 24 well plates), on the tube rack it is 20 mm. The tube rack was designed for 15 ml centrifuge tubes, and the threaded part of the tubes is 19.30 mm in diameter.